Our Strength

Low in running cost

Running cost can be largely reduced compared with conventional method.

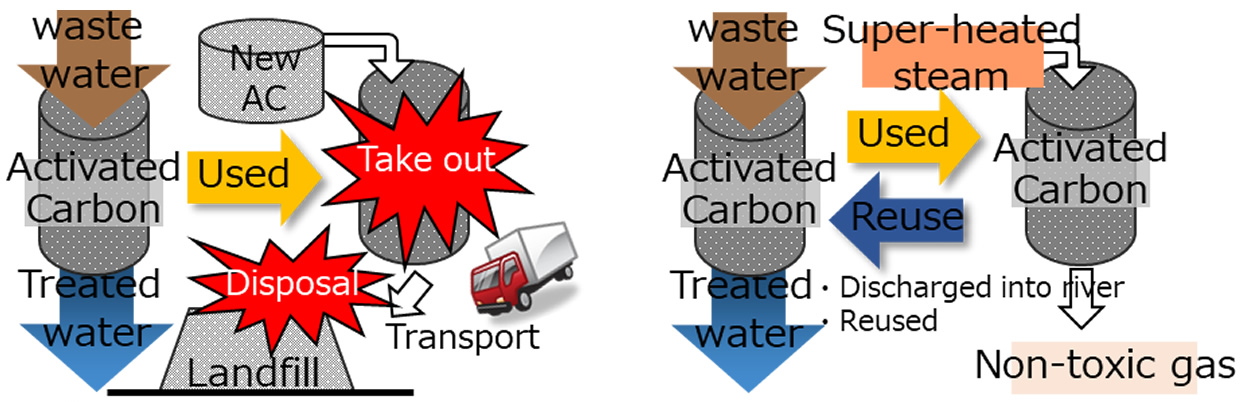

| Conventional method |

Method |

JTOP method |

| Necessary to take-in/out AC |

Effort |

Full automatic Regeneration |

| A microbe propagates in column |

Hygienic |

Sterilizing by regeneration heating |

| AC is not reused⇒Disposal |

Waste |

AC is reused. |

- Cost of buying new AC

(Approx.US$2000 /1 m3)

Price of new AC

(Approx.US$ 4.5 /1 kg)

- Waste disposal costs

(Approx.US$300~400/1m³)

- Manpower costs of removing AC

(Approx.US$100~200/1m³)

Total Approx.US$2500/m³

|

Running Cost |

- Electric bill or gas fee during regeneration

Cost for regeneration of AC (Below US$ 1 /1 kg)

Total Approx.US$25/m³

|

1/100

Estimate for regeneration cost per 1m³ of water treatment

Cost for wastewater treatment of 100 m³with 1m³ of activated.

(The amount of throughput varies depending on the amount of wastewater and the quality of the water)

- Throughput

- 100m³/day

- Size of AC Column

- Large AC1m³ (500kg)

- Heater

- 約18kW 4h×2 $19/day

- Pump

- 約3.7kW 10h $5/day

- Control panel

- 約1kW 24h $3/day

- Total

- $27/day

- Per 1m³

- $0.27/m³

Note: Estimated electric bill as $0.13/kWh. In the absence of steam supply, costs related to steam supply occur separately.

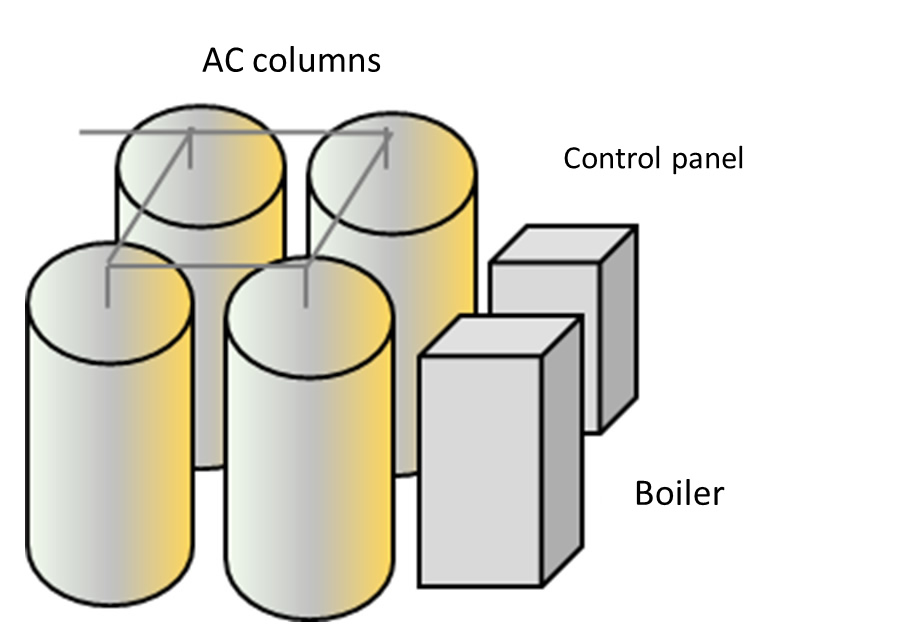

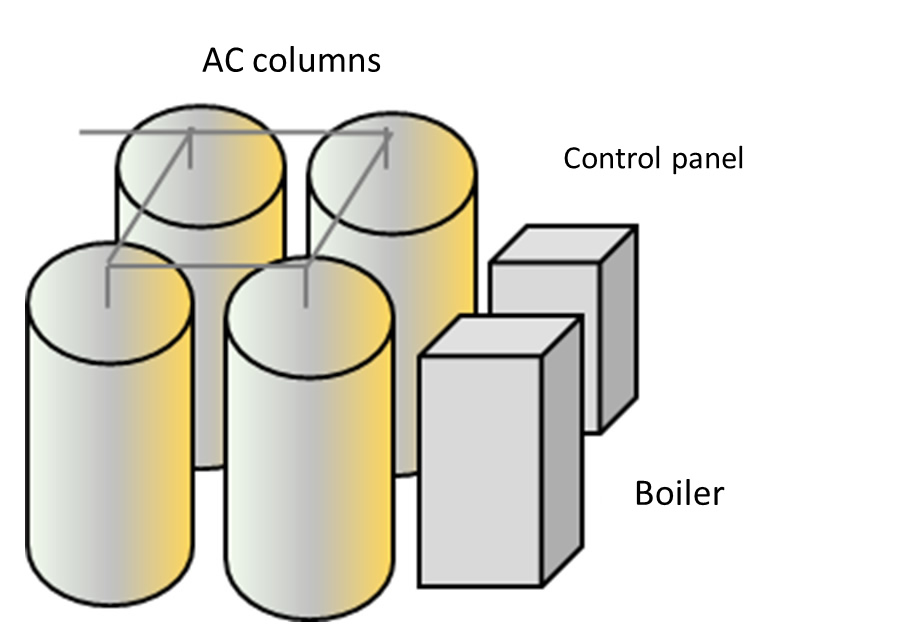

Space saving design

Compact designed equipment.

Incidental equipment such as stirring or settling tank are unnecessary.

Installed in 2013

Footprint ca. 12m³

throughput 50 t/day

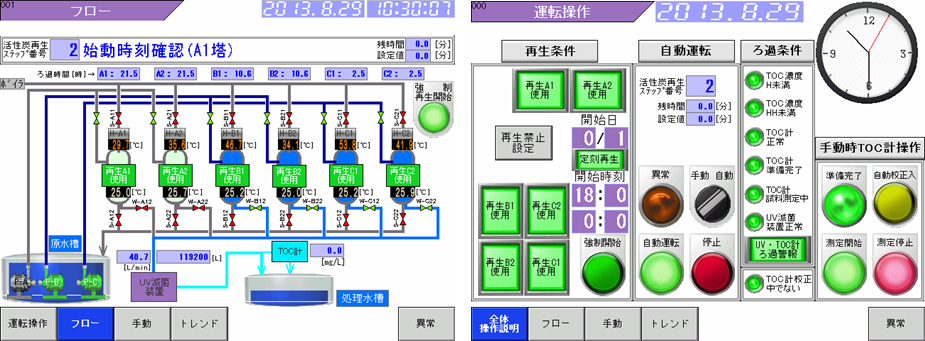

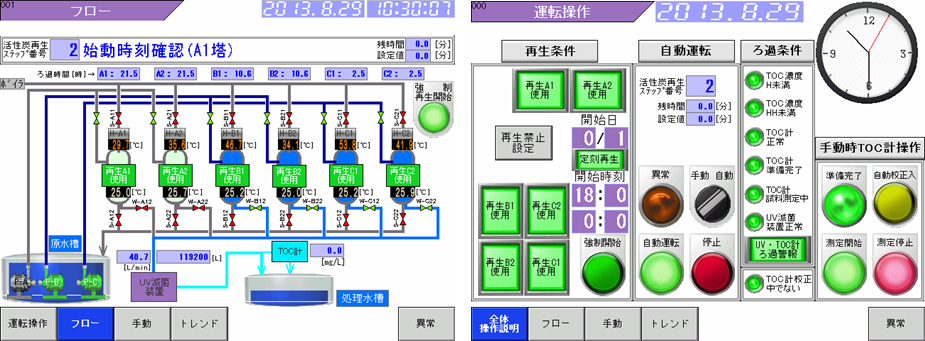

Simple to set-up and operate

No engineering work required when installing, because it’s unit type.

Operation with automatic control. Easy operation with touch panel setting.

Screen of Touch panel

The activated carbon column can be easily increased as the amount of wastewater is increased.

Wide application for various kinds of water and gases

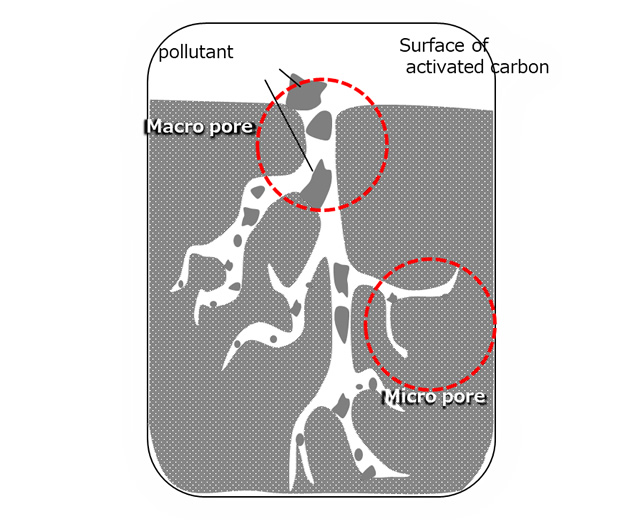

Specific activated carbon can adsorb various materials of different sizes and properties.

Structure of specific activated carbon

Possible to treat substances that are difficult to process biologically

Harmful organic matter

| Items |

Conc. of raw water(mg/L) |

Conc. of treated water(mg/L) |

| Dichloromethane (Regulation value: 0.2mg/L) |

0.25 |

Less than 0.01 |

| Phenol (Regulation value: 5mg/L) |

26,000 |

1.2 |

| Trichlorethylene (Regulation value: 0.1 mg/L) |

500 |

0.02 |

| Dimethylformamide |

1,700 |

16 |

| Ethyl acetate |

1,500 |

Less than 0.01 |

| Toluene |

34 |

0.03 |

| Glycidol |

3,000 |

0 |

| Phenylenediamine |

3 |

N/D |

Persistent organic matter

| Items |

Conc. of raw water(mg/L) |

Conc. of treated water(mg/L) |

| 1,4-dioxane(Regulation value: 0.5 mg/L) |

150 |

0.4 |

| Propyleneglycol-1-monomethylether-2-acetate |

COD 20,000 |

COD 100 |

| Polyethylene/polypropylene |

COD 250 |

COD 50 |

Exhaust gas

| Item |

Before treatment(mg/L) |

After treatment(mg/L) |

| Methyl methacrylate |

489 |

3 |

| Odor Index |

24 |

8 |

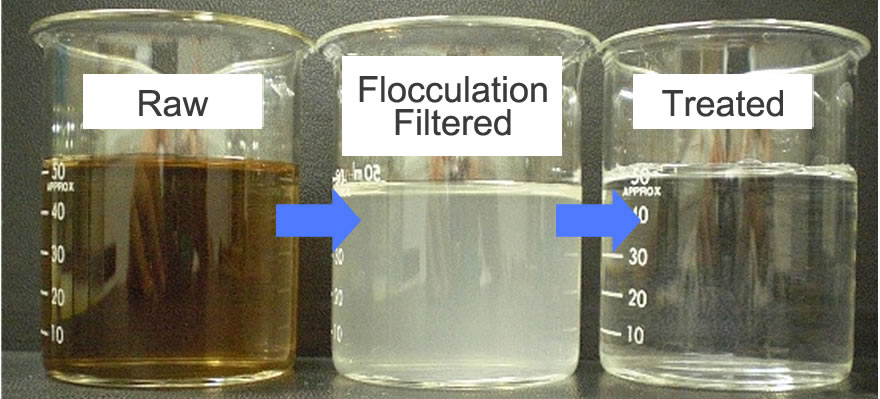

Water containing Suspended Solid (SS)

| Item |

Conc. of Raw (mg/L) |

Conc. of treated (mg/L) |

| BOD |

430 |

31 |

※Appropriate flocculant is to be selected before coagulation treatment.

※Equipment for coagulation treatment is to be designed.

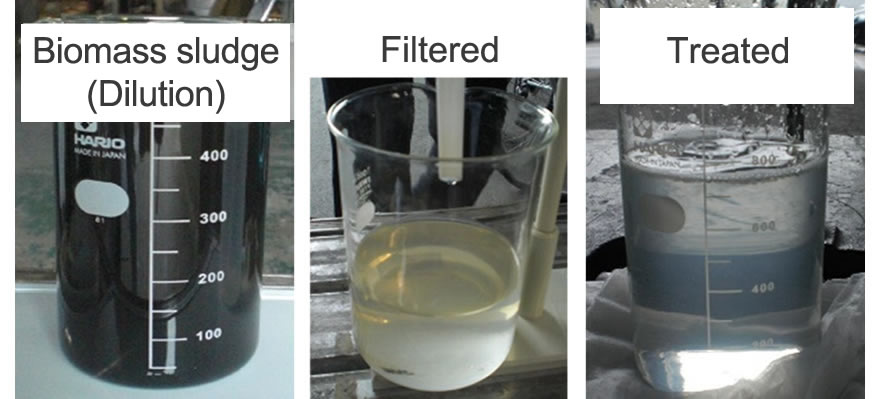

Biomass fermentation digested slurry

| Item |

Conc. of Raw (mg/L) |

Conc. of treated (mg/L) |

| COD |

160 |

4 |

| BOD |

240 |

9 |

| E. coli |

1,000/1cm³ |

N/D |

| Bacteria |

10,000 (CFU/mL) |

Less than 10 |

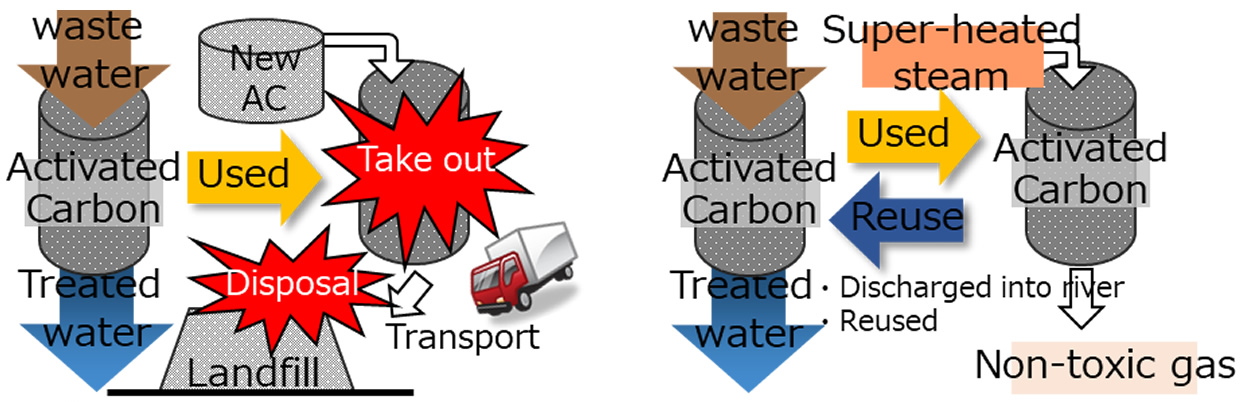

Eco-friendly

Activated carbon is regenerated and reusable. It reduces a huge energy consumed during incineration.

Reusing treated water to promote zero-emissions at the factory.